Winter is the perfect time to do the maintenance of your piston pump, to keep it running smoothly and lasting longer. This guide covers three main areas: oil maintenance, parts tightness checks, and gland packing inspections.

Keeping an eye on your oil is super important for your piston pump’s health. Pumps use gears, an eccentric, a connecting rod, and a crosshead—all metal parts that need lubrication to work properly. The right oil not only protects these parts but also makes your pump last longer.

- Checking Oil Quality

Clean oil is key. It should look clear and golden and feel smooth. If your oil looks dark and gritty, it’s time to drain and replace it. A grey, foamy look means there’s water in the back end of the pump, and you should clean it out right away.

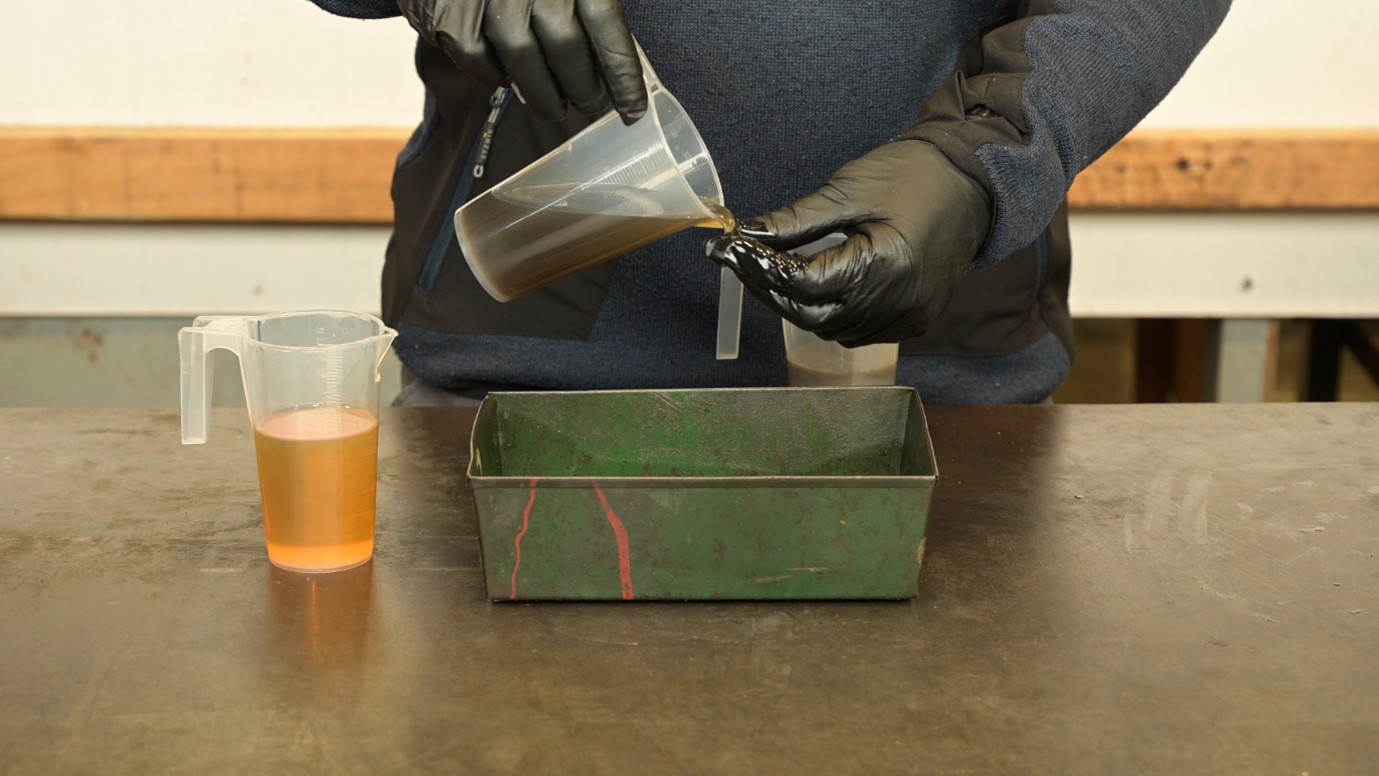

- Draining the Oil

To drain the oil, find the drainage plug. For smaller pumps, it’s usually at the bottom of the back end, while medium and larger pumps often have it on the side. If your pump is New Zealand-made, we recommend using SAE 30 oil, but larger Anderson pumps need EP 90 oil.

As your pump gets older, the gears and other parts can wear down, affecting how tightly everything fits together. Keeping everything nice and tight is crucial for smooth operation.

- Testing for Wear

To check for wear, turn the pulley. A well-maintained pump should respond quickly without much delay. If you hear a knocking sound, it could mean there’s a gap between the internal parts, which can lead to problems down the line.

- Gear Wear Check

Worn teeth on gears can really affect how well your pump works. If you compare the worn teeth to new ones, the difference is usually clear. If they’re excessively worn, it’s a good idea to replace them to get things back to normal.

- Checking for Knocking Sounds

It’s normal for new pumps to knock a bit under heavy loads, but if you hear knocking under light loads, it’s time to look inside. If you’re not sure about your pump’s condition, don’t hesitate to reach out to your local agent for help.

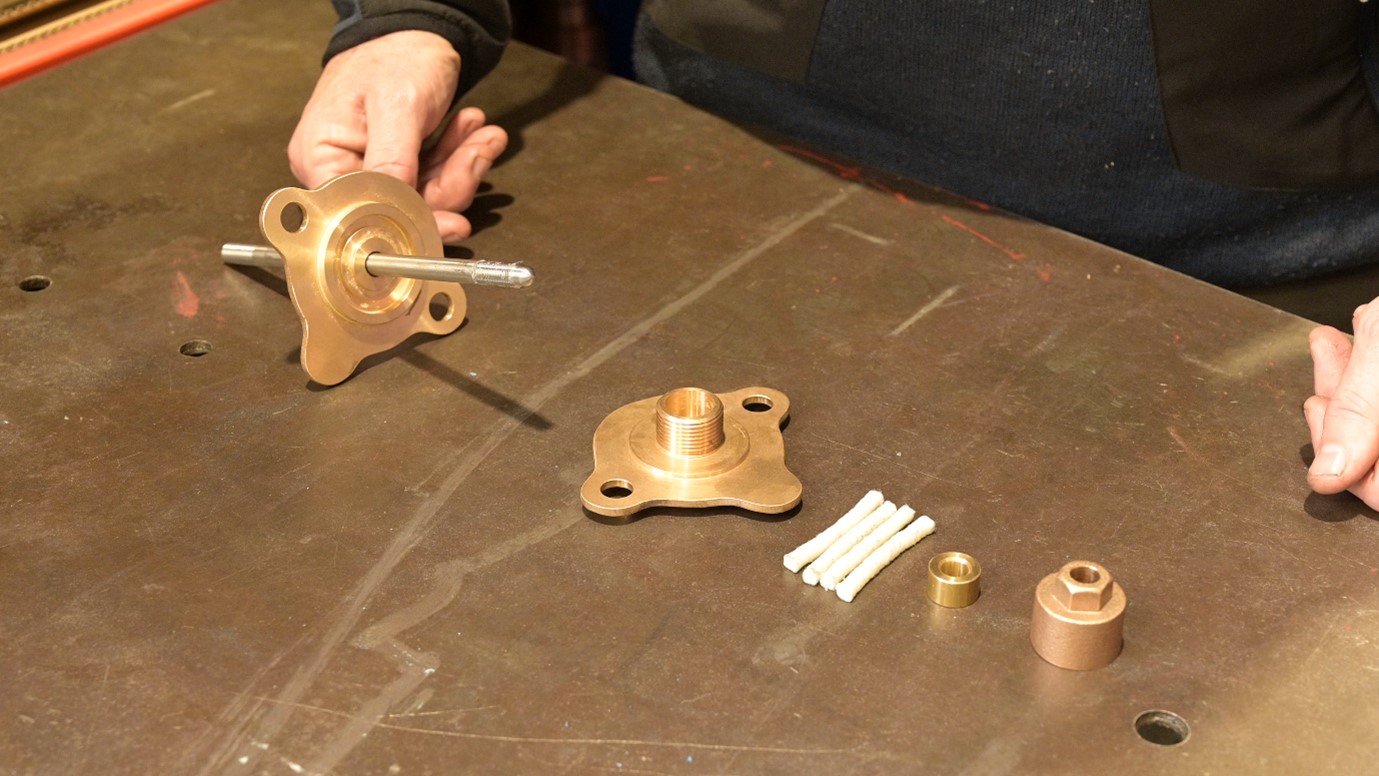

Gland packing is essential for keeping water from leaking out and air from flowing back in. Keeping this part in good shape is crucial to avoiding leaks that can wear out your pump.

- Understanding Gland Packing

Gland packing is a rope-like material that’s mixed with high-temperature waxes. It comes in pre-cut pieces or by the meter. Over time, it can wear out or break down, leading to leaks.

- Identifying Leaks

A few drops of water are normal, but if you see water squirting or flowing, it’s time to do something. Start by tightening the gland nut with a gland spanner. If that doesn’t stop the leak, you might need to replace the gland packing.

- Replacing Gland Packing

When you’re replacing gland packing, make sure to overlap the ends of the old packing with the centre of the new piece for a tight seal. If leaks persist after you replace it, check the gland plate, follower, and nut, as well as the plunger rod for signs of wear.

Hope you find this guide helpful. Check out the full explanation in the YouTube video below: